What Makes PE Coated Paper Rolls Unique?

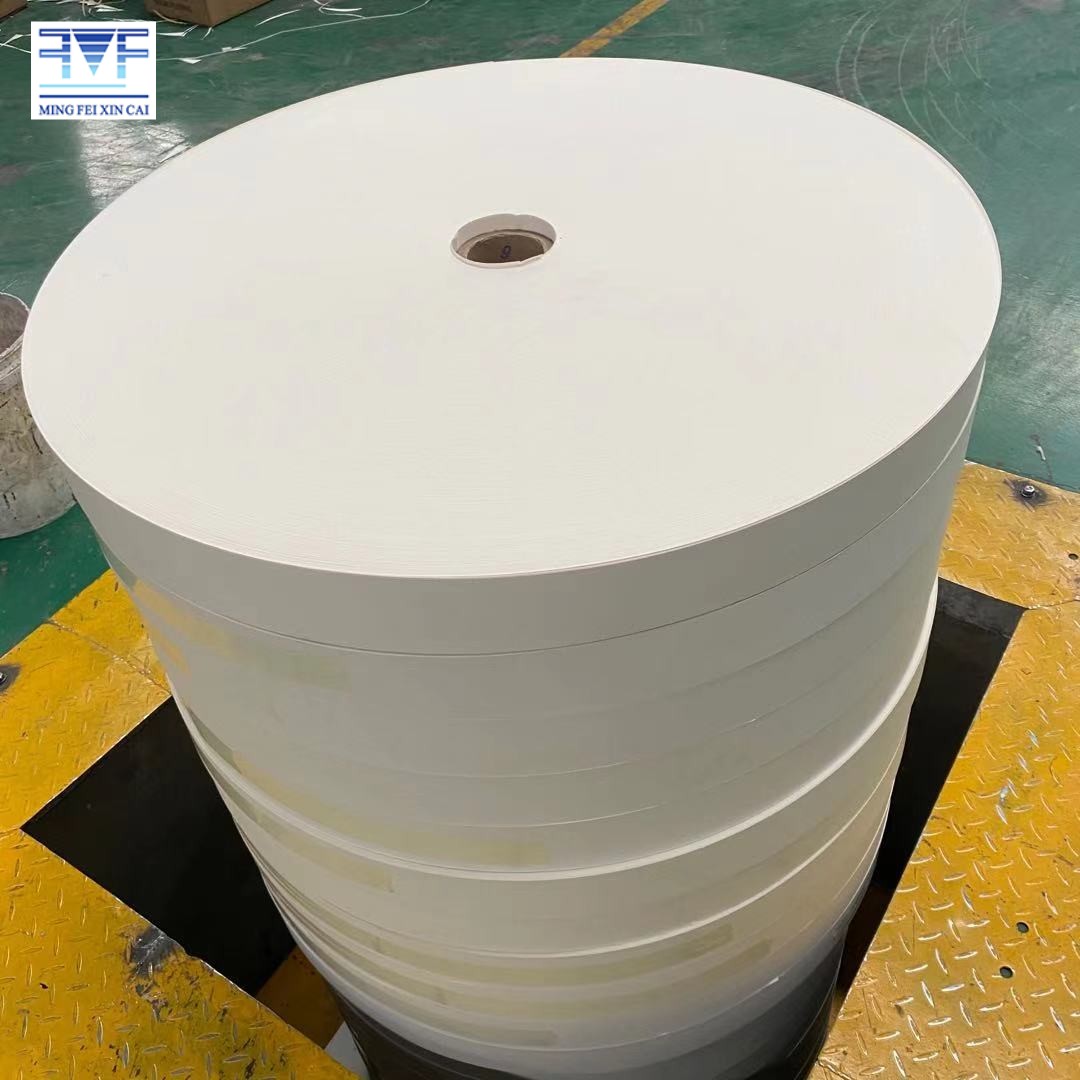

PE coated paper rolls are made by applying a layer of polyethylene (PE) to paper through a coating process, which typically involves extrusion or lamination. This process forms a strong bond between the paper and the plastic, ensuring that the material benefits from both the paper's natural qualities—such as strength and flexibility—and polyethylene's protective properties, such as water resistance, moisture retention, and durability.

The combination of paper and plastic allows PE coated paper to offer a superior level of performance in packaging. The material is lightweight yet robust, and it is widely used for food packaging, protective wraps, industrial applications, and consumer products. However, the real story lies in the advances in the manufacturing process that are making PE coated paper even more efficient, sustainable, and versatile.

Advancements in PE Coating Technology

Over the years, the technology used to produce PE coated paper rolls has significantly improved. Innovations in coating techniques, equipment, and materials have contributed to enhanced performance and a reduction in environmental impact. Here are some key developments:

Extrusion Coating and Lamination: The extrusion process, where molten polyethylene is directly applied to paper, has undergone several improvements, resulting in smoother coatings, better adhesion, and more uniform layers. Innovations in lamination techniques, which involve fusing polyethylene to the paper surface under heat and pressure, have also allowed for increased durability and flexibility.

Multilayer Coatings: Traditional PE coating involves a single layer of polyethylene applied to paper. However, recent technological developments have led to the creation of multilayer coatings. These coatings provide even greater protection against moisture, oils, and other external factors, while maintaining or enhancing the paper’s structural integrity. Multilayer coatings are particularly useful in the food industry, where packaging needs to provide superior barrier properties to preserve freshness and quality.

Coating Thickness Control: Advances in coating technology have made it possible to control the thickness of the polyethylene coating with high precision. By regulating the thickness, manufacturers can optimize the performance of the coated paper, ensuring that it provides the right balance of protection without excessive use of material. This not only improves the cost-effectiveness of production but also reduces waste.

Bio-Based Polyethylene: One of the most significant advancements in the field is the introduction of bio-based polyethylene, which is derived from renewable resources such as sugarcane. Bio-based PE offers similar properties to conventional polyethylene but with a reduced carbon footprint. This development aligns with the increasing demand for sustainable packaging solutions, and manufacturers are now working to incorporate bio-based polyethylene into PE coated paper rolls, providing a more eco-friendly alternative to traditional plastic coatings.

Recycling and Waste Management: Recycling PE coated paper has always been a challenge due to the difficulty of separating the plastic from the paper. However, technological advancements in recycling processes have made it possible to recycle PE coated paper more efficiently. New techniques, such as solvent-based extraction and separation technologies, are helping manufacturers reclaim polyethylene from the paper and recycle both materials separately. This development is crucial for enhancing the sustainability of PE coated paper and reducing the environmental impact of plastic waste.

Enhancing Durability and Performance

As the demand for PE coated paper rolls grows, so too does the need for packaging materials that can withstand extreme conditions. Recent advancements in coating formulations have made PE coated paper rolls more durable and capable of handling tougher environments.

Heat and Cold Resistance: In food packaging, PE coated paper rolls are subjected to various temperatures, from freezing cold to high heat. To meet this need, manufacturers have developed coatings that enhance the material’s ability to withstand extreme temperatures without compromising the integrity of the paper. This is particularly important in the transportation and storage of perishable goods.

Grease and Oil Resistance: For packaging applications in the food industry, particularly in items like pizza boxes and takeout containers, PE coated paper needs to offer effective resistance to grease and oils. New coating formulations and techniques ensure that the PE layer provides a stronger barrier, preventing leaks and stains from compromising the packaged food.

Water Resistance: Another important feature of PE coated paper is its ability to resist water. With advancements in coating techniques, PE coated paper can now offer even better water resistance, making it ideal for use in products that require protection from moisture, such as food wrappers and medical packaging.

English

English Español

Español عربى

عربى.jpg?imageView2/2/format/jp2)

View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >>.png?imageView2/2/format/jp2) View More >>

View More >>.jpg?imageView2/2/format/jp2) View More >>

View More >> View More >>

View More >>.png?imageView2/2/format/jp2) View More >>

View More >> View More >>

View More >> View More >>

View More >>.jpg?imageView2/2/format/jp2) View More >>

View More >>